IRIS-Automation

IRIS-Automation

Friars House

Manor House Drive

Coventry

CV1 2TE

Great Britain and Northern Ireland

Telephone07706961744

About us

IRIS Automation specialises in bespoke machine learning solutions, helping manufacturers drive efficiency. Our advanced technology integrates seamlessly into production lines for tasks such as:

- Defect Detection: Identifies imperfections using image analysis, reducing waste and enhancing product quality

- Object Detection: Tracks items in real-time for accurate sorting and control

- Measurement: Ensures precise dimensions for perfect product fit

- Optical Character Recognition: Converts visual data to text for streamlined inventory management

- Predictive Maintenance: Monitors machinery, predicts failures, and minimizes downtime.

Our solutions optimise production lines, minimise errors, enhance quality, and boost output while lowering costs.

Our product groups

- Digital transformation (administrative and operational processes, customer management, projects, sustainability)

- Intelligent data processing, customer data management (data analysis and management, data security)

- Big-Data

- Data-analytics

- Automated driving (electrical components for autonomous driving, robocabs, sensors, actuators, artificial intelligence, cameras, ultrasonics, lateral and horizontal driver assistance systems)

- Research projects

- Factory/ Production Equipment

- Automation Equipment

- Inspection/Measurement Equipment

- Process Control Equipment

More about us

IRIS Automation specialising in bespoke machine learning, predictive maintenance, IoT, edge computing, and large language models. We partner with manufacturers to drive efficiency and innovation. Our cutting-edge technology integrates seamlessly into production lines, enhancing quality, reducing waste, and delivering competitive advantages

Keywords

- Machine Learning

- Predictive Maintenance

- IoT

- Production Line Efficiency

- Quality Control

Our Products

Optical Character Recognition with Deep Learning

Deep learning-powered OCR transforms visual data into precise, actionable text—enabling seamless traceability, efficient inventory management, and accurate label verification. Key capabilities include intelligent multimodal analysis that fuses text, image, and context; semantic extraction for meaningful insights; and image-to-text conversion for streamlined workflows. With exceptional accuracy and adaptability, this technology empowers industries to optimize operations, ensure compliance, and drive high operational efficiency.

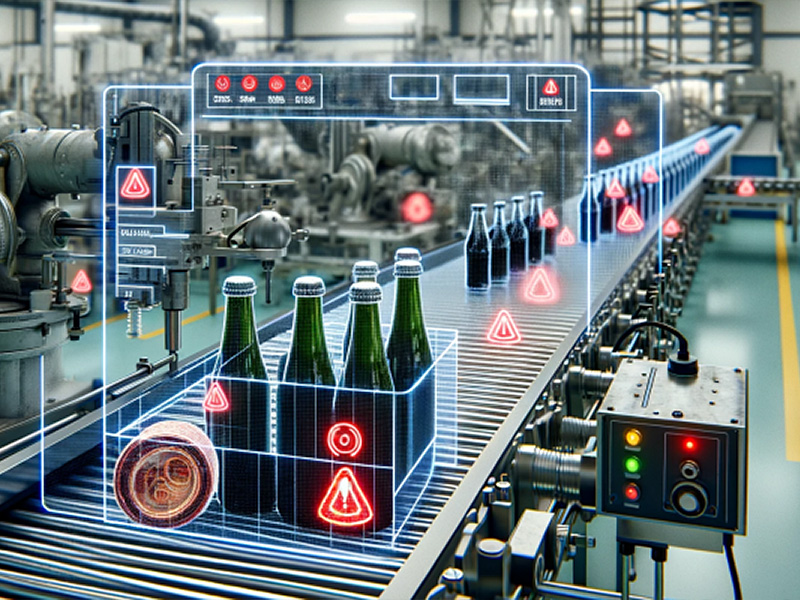

SmartVision AR

SmartVision AR is an AI-powered solution revolutionising industrial fault detection and inspection. By combining Augmented Reality (AR) with advanced AI, it offers unmatched accuracy and efficiency. It includes real-time fault detection, lightweight AR equipment, user-friendly visualisation and human-in-the-loop feedback allowing operators to validate or override AI detections through the AR interface. It supports rapid deployment on new production lines through Transfer Learning while its feedback loop enhances system accuracy over time through Reinforcement Learning, making the system adaptive and increasingly precise. SmartVision AR reduces false positives, minimises downtime, lowers training costs, and enhances productivity with accurate, immediate fault detection.

IRIS AI Vision

IRIS AI Vision enhances production line automation and optimisation using bespoke AI algorithms and machine learning solutions delivered through a user friendly interface. It rapidly trains the system to handle a range inspection and key industrial tasks:

- Defect Detection: Identifies imperfections using advanced image analysis, reducing waste and ensuring top-quality products.

- Object Detection: Tracks and manages items in real-time for accurate sorting, counting, and control.

- Measurement: Ensures precise dimensional accuracy, guaranteeing product components meet exact specifications.

Our solutions minimise errors, enhance product quality, and increase production output, leading to significant cost savings